Schmetz needles are globally recognized for their quality and precision, serving both crafters and industrial users. With a vast selection, there’s a Schmetz needle for every sewing project, ensuring optimal results with various fabrics and threads.

Schmetz needles stand as a hallmark of quality in the sewing world, trusted by both hobbyists and professionals. With a legacy built on precision engineering, Schmetz offers a comprehensive range of needles designed to tackle diverse fabrics and sewing challenges. From delicate silks to heavy denims, their needles are crafted to deliver optimal stitch formation and prevent fabric damage.

The key to successful sewing often lies in selecting the right needle, and Schmetz simplifies this process with their innovative color-coding system. This guide will navigate you through the anatomy of Schmetz needles, decoding their color codes, and exploring the specific applications of various needle types. Whether you’re a seasoned seamstress or a beginner, understanding Schmetz needles will elevate your sewing projects to new heights of precision and quality.

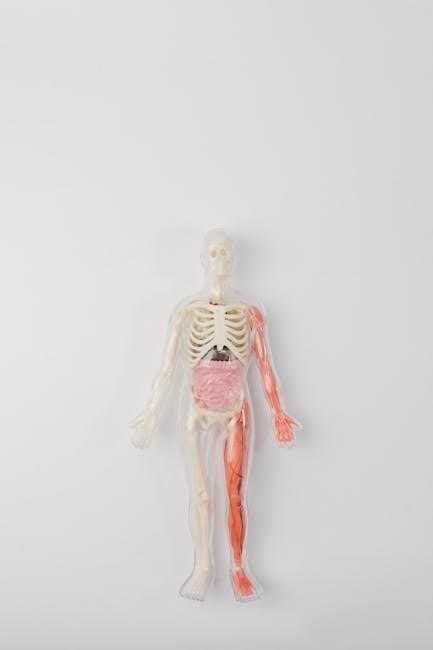

Understanding Needle Anatomy

To effectively utilize Schmetz needles, understanding their anatomy is essential. Each component plays a crucial role in stitch formation and fabric interaction. The needle’s shank, the part inserted into the sewing machine, features a flat side ensuring proper alignment. The shaft, or blade, connects the shank to the eye and point. Its length and thickness vary depending on the needle type.

The eye, the hole through which the thread passes, comes in various shapes and sizes to accommodate different thread weights. The point and tip are designed to penetrate fabric, with variations optimized for different materials. Finally, the scarf, a small indentation above the eye, assists in loop formation, allowing the hook or looper to catch the thread and create a secure stitch. Recognizing these features empowers informed needle selection.

Shank

The shank is the uppermost part of the needle, designed for secure insertion into the sewing machine. Its primary function is to provide a stable and precise connection, ensuring the needle operates correctly within the machine’s mechanism. A key feature of the shank is its flat side, which is universally present in home sewing machine needles, specifically those adhering to the 130/705 H system.

This flat side is crucial for proper needle orientation, guaranteeing that the eye is correctly aligned with the hook or looper. Without this feature, timing issues and skipped stitches can occur. Always ensure the shank is fully inserted and properly oriented according to your sewing machine’s manual to maintain optimal stitching performance and prevent damage to both the needle and the machine.

Shaft

The shaft, also known as the blade, is the main body of the needle, extending from the shank down to the eye. Its length and thickness are crucial factors influencing the needle’s performance with different fabrics. A thicker shaft provides greater strength, ideal for dense materials like denim or leather, reducing the risk of needle breakage or bending during sewing.

Conversely, a thinner shaft is better suited for delicate fabrics like silk or fine knits, minimizing the potential for creating large or unsightly holes. The shaft’s design ensures that the needle can penetrate the fabric cleanly and efficiently, creating a smooth path for the thread to follow. Selecting the correct shaft thickness is essential for achieving professional-looking stitches and preventing fabric damage.

Eye

The eye is the small hole located at the lower end of the needle’s shaft, through which the thread passes. Its shape and size are carefully designed to accommodate different thread types and thicknesses, ensuring smooth and consistent thread delivery during sewing. A larger eye is typically used for thicker threads, such as those used in topstitching or embroidery, allowing the thread to move freely without fraying or breaking.

Conversely, a smaller eye is suitable for finer threads, preventing them from slipping or looping excessively. The eye’s polished surface minimizes friction, reducing the risk of thread breakage and ensuring smooth stitch formation. Specialized needles, like topstitch needles, feature an elongated eye to better accommodate thicker threads and prevent shredding. The eye’s design is crucial for achieving consistent stitch quality and preventing thread-related issues during sewing.

Point & Tip

The point and tip of a Schmetz needle are critical for fabric penetration and stitch formation. The shape, length, and size of the point vary significantly depending on the needle type and its intended use. Sharp points, like those found on microtex needles, are designed for tightly woven fabrics requiring precision. Ballpoint needles, on the other hand, feature a rounded tip to gently separate knit fibers, preventing damage.

The point’s geometry affects the needle’s ability to pierce the fabric cleanly, influencing stitch quality and minimizing skipped stitches. Leather needles have a cutting point to slice through tough materials, while universal needles offer a slightly rounded point suitable for various woven fabrics. Choosing the correct point ensures optimal fabric penetration, reduces stress on the material, and promotes consistent, professional-looking results. The point is vital for successful sewing.

Scarf

The scarf of a Schmetz needle is a crucial element in the stitch formation process. It is a small indentation or groove located above the eye of the needle, on the back side. Its primary function is to allow the hook or looper of the sewing machine to grab the thread loop, which is essential for creating a secure stitch. The shape and size of the scarf are carefully engineered and will vary according to needle type, to ensure compatibility with different fabrics and sewing machine mechanisms.

A properly designed scarf facilitates smooth and reliable loop formation, preventing skipped stitches and ensuring consistent stitch quality. Different needle types will have different scarf designs based on the fabric. The scarf works with the throat plate, creating a stitch.

Decoding Schmetz Needle Color Codes

Schmetz needles feature a color-coding system on the shank, enabling quick identification of needle type and size. This system simplifies needle selection, ensuring the right needle is used for each project. The color code consists of two bands: an upper band indicating the needle type and a lower band indicating the needle size.

The upper color band denotes the needle type, such as Universal, Stretch, Jersey/Ball Point, Jeans/Denim, Leather, Microtex, or Topstitch. Each type has a specific color, like white for Universal or yellow for Stretch. The lower color band indicates the needle size, such as 70/10, 80/12, or 90/14, with each size assigned a unique color.

Upper Color Band (Needle Type)

The upper color band on a Schmetz needle is crucial for quickly identifying the needle’s intended use. Each color corresponds to a specific needle type, designed for particular fabrics and sewing applications. For example, a white band signifies a Universal needle, suitable for a wide range of woven and knit fabrics. A yellow band indicates a Stretch needle, ideal for highly elastic materials like lingerie fabrics.

Similarly, orange represents Jersey needles, designed for cotton knitwear and tulle. Blue denotes Jeans/Denim needles, while brown indicates Leather needles. Purple signifies Microtex needles, perfect for precision stitching on delicate fabrics. Recognizing these colors allows sewers to select the optimal needle for their project, ensuring quality stitches and preventing fabric damage.

Lower Color Band (Needle Size)

The lower color band on Schmetz needles indicates the needle size, a crucial factor in achieving optimal sewing results. This band provides a quick visual reference for selecting the appropriate needle thickness for the chosen fabric and thread. Needle sizes are typically represented by two numbers, such as 70/10 or 80/12, indicating the needle’s diameter in both metric and imperial units.

A smaller number signifies a finer needle, suitable for lightweight fabrics like silk or chiffon, while a larger number indicates a thicker needle, ideal for heavier materials such as denim or canvas. Selecting the correct needle size ensures that the needle can penetrate the fabric without causing damage or skipped stitches, resulting in a smooth and professional finish. This system simplifies needle selection, particularly for those working with diverse fabric types.

Common Schmetz Needle Types and Their Uses

Schmetz offers a wide array of needle types, each designed for specific fabrics and sewing applications. Understanding these types is essential for achieving optimal stitch quality and preventing damage to your materials. Among the most common are universal needles, suitable for a variety of woven and knit fabrics. Stretch needles are designed for highly elastic materials, preventing skipped stitches.

Jersey or ballpoint needles feature a rounded tip that gently separates fabric fibers, ideal for cotton knitwear and materials with elastane. Jeans or denim needles are extra-strong, perfect for penetrating heavy-duty fabrics. Leather needles have a chisel point to pierce through leather without tearing. Microtex needles are exceptionally sharp for precision stitching on tightly woven fabrics, while topstitch needles have an extra-large eye for thicker threads. Selecting the right needle guarantees professional results.

Universal Needles

Universal needles are the workhorses of the sewing world, designed to handle a wide array of woven and knit fabrics. Their slightly rounded point makes them suitable for most general sewing tasks, offering versatility for various projects. These needles are a great starting point if you’re unsure which type to use, accommodating numerous fabric types with ease.

Often the first choice for beginners, universal needles perform well with cotton, linen, and many synthetic blends. They are readily available in various sizes to match different thread weights and fabric thicknesses. However, for specialized materials like stretch knits or heavy denim, a dedicated needle type will always yield superior results. Always check the needle size and condition before sewing.

Stretch Needles

Stretch needles are specifically engineered for highly elastic fabrics, such as spandex, Lycra, and swimwear materials. Their unique design prevents skipped stitches and damage to delicate fibers, ensuring smooth and professional-looking seams. The yellow color code on Schmetz stretch needles makes them easily identifiable in your sewing kit.

These needles feature a special eye and scarf that work together to create a larger loop, allowing the hook to catch the thread reliably, even when the fabric is stretched. Using a stretch needle on these materials minimizes the risk of popped seams and ensures the fabric retains its original shape. They are also excellent for lingerie and similar materials with a high degree of elasticity. Always pair with a suitable thread.

Jersey/Ball Point Needles

Jersey or ball point needles are designed specifically for knit fabrics, including cotton knitwear, jersey, and tulle. Unlike sharp needles that can pierce and damage the loops of knit fabrics, ball point needles have a rounded tip that gently pushes the fibers aside, preventing runs and snags. This design helps preserve the integrity of the fabric and ensures a smooth, even stitch.

These needles are particularly useful when working with materials containing elastane, as they minimize the risk of broken threads and distorted stitches. The orange color code on Schmetz jersey needles allows for quick identification. Using the correct needle type is crucial for achieving professional results when sewing with knit fabrics. Available in various sizes to suit different weights of knits.

Jeans/Denim Needles

Jeans or denim needles are specifically engineered to handle the dense and heavy nature of denim and similar tightly woven fabrics. These needles feature a strong, sharp point designed to penetrate multiple layers of thick material without breaking or bending. The reinforced shank reduces needle breakage and skipped stitches, ensuring consistent and reliable performance.

The blue color code on Schmetz jeans needles makes them easily identifiable. These needles are ideal for sewing jeans, denim jackets, and other heavy-duty projects. Available in various sizes to accommodate different weights of denim, they are a must-have for anyone working with tough fabrics. Using the correct needle size and type is essential for achieving professional-looking results and preventing damage to both the fabric and the sewing machine.

Leather Needles

Leather needles are designed explicitly for sewing leather and other tough, non-woven materials. Unlike standard needles that push through fabric threads, leather needles have a specialized cutting point that slices through the leather, creating a clean and precise stitch. This cutting action prevents damage to the leather and ensures a professional finish.

The brown color code on Schmetz leather needles helps users quickly identify them. These needles are available in various sizes to suit different leather thicknesses. When working with leather, it’s crucial to use a leather needle to avoid skipped stitches, broken threads, and damage to the material. Leather needles are essential for creating durable and aesthetically pleasing leather goods such as bags, belts, and garments. Selecting the correct needle size ensures optimal performance and longevity of your sewing projects.

Microtex Needles

Microtex needles are crafted for precision sewing with tightly woven fabrics such as microfiber, silk, and synthetic materials. The slender, acute point of a Microtex needle allows it to pierce through these dense fabrics without causing damage or skipped stitches. This needle type is essential when achieving flawless seams and professional finishes on delicate projects.

Identified by a purple color code on Schmetz needles, Microtex needles come in various sizes to accommodate different fabric weights. They are particularly useful for projects that demand accuracy and a refined appearance. When using Microtex needles, it’s important to select the appropriate thread and tension settings on your sewing machine to ensure optimal results. These needles are also suitable for creating buttonholes and other detailed work where precision is paramount.

Topstitch Needles

Topstitch needles are designed with an extra-large eye to accommodate thicker topstitching threads, metallic threads, and other specialty threads. This larger eye prevents shredding and breakage of delicate or heavier threads, ensuring smooth and even stitching. The sharp point of a topstitch needle allows it to penetrate multiple layers of fabric with ease, making it ideal for decorative stitching, quilting, and creating prominent seams.

These needles are especially useful for adding a professional touch to your sewing projects. Schmetz topstitch needles are easily identified and available in various sizes to match your fabric and thread requirements. They are a favorite among quilters and garment makers. Using a topstitch needle can significantly enhance the appearance of your projects, providing a clean and polished finish.

Twin and Triple Needles

Twin and triple needles from Schmetz offer the opportunity to create multiple rows of stitches simultaneously, adding decorative and functional elements to your sewing projects. A twin needle consists of two needles mounted on a single shank, while a triple needle features three needles on one shank. These needles are designed for use with conventional household sewing machines that have a zig-zag function.

When using twin or triple needles, you’ll need multiple spools of thread to feed each needle individually; This setup allows you to create parallel rows of stitching, perfect for decorative embellishments, pintucks, and creating a faux-serged edge. Schmetz twin and triple needles are available in various sizes and types, including universal and stretch, allowing you to customize your stitching to suit different fabrics and project requirements. They enhance creative possibilities.

Needle Size Guide

Understanding needle sizes is crucial for successful sewing. Schmetz needles use a dual numbering system, with both a metric (European) and an American size indicated on the packaging. The metric size ranges from 60 to 130, representing the needle’s diameter in hundredths of a millimeter. The American size ranges from 8 to 21. A smaller number indicates a finer needle for lightweight fabrics.

A larger number signifies a heavier needle for thicker materials. Selecting the correct needle size is essential to prevent skipped stitches, fabric damage, and thread breakage. Always refer to your fabric’s weight and type when choosing a needle size. Lighter fabrics like silk or chiffon require finer needles (60/8 to 70/10), while heavier fabrics like denim or canvas need larger needles (90/14 to 110/18 or higher). Test sewing is recommended.